Which Material is More Suitable for Sacrificial Anodes?

In the selection of sacrificial anode materials, it is necessary to combine the use environment, protection requirements and cost for comprehensive consideration.

The Following is a Specific Analysis

Magnesium Anode:

Advantages: Magnesium anode has a higher driving voltage and is suitable for soil or freshwater environments with high resistivity. Its potential is negative and its current efficiency is high, which can provide sufficient protection current in high resistivity environments.

Disadvantages: The self-corrosion rate of magnesium anode is relatively fast, the service life may be short, and it may be affected by chemical corrosion in certain environments.

Aluminum Anode:

Advantages: Aluminum anode has a longer service life, usually 5 times that of magnesium anode, and has higher electrochemical activity and power generation per unit mass. The activity of aluminum anode alloy is slightly higher than that of zinc, and it is suitable for seawater and salt water environments. It has the advantages of light weight, good corrosion resistance, and high cost performance.

Disadvantages: Aluminum anode is prone to passivation in alkaline environments, resulting in reduced current efficiency, and there may be local corrosion problems in some environments.

Zinc Anode:

Advantages: Zinc anode has a moderate potential, relatively stable current efficiency, is widely used in seawater, has a relatively low self-corrosion rate, and can provide protection current continuously and stably.

Disadvantages: Zinc anodes are easily corroded by chloride ions in seawater environments, resulting in performance degradation and a relatively short service life.

It's hard to pick a winner right now. Magnesium provides the highest voltage, but aluminum lasts longer (5 times more than magnesium) and aluminum anode alloys are slightly more active than zinc.

So Why is Zinc the Most Common Material?

It's an inexpensive material that does work well in most saltwater applications. Pure aluminum as an anode material is useless because it immediately forms a layer of oxide, isolating it from the outside world, so that it cannot be further consumed, preventing the anode from working effectively and failing to achieve the purpose of protection.

It was not until the middle of the 20th century that it was discovered that adding a small amount of zinc and indium to aluminum could overcome the problem of aluminum forming an insulating oxide layer, and aluminum alloys were developed.

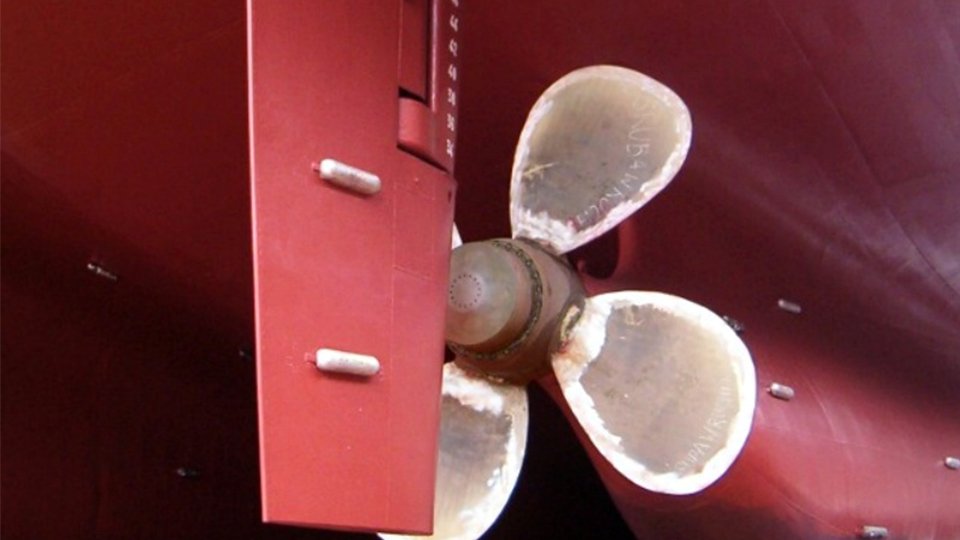

What Equipment Needs to be Protected?

The type of ship will determine how it is protected. For example, a fiberglass hull with an inbuilt engine requires much less protection than an aluminum hull or aluminum stern-drive boat. The most reliable way to determine if a boat is fully protected is to measure its cathodic protection voltage, or "hull potential".

River vessels are mainly bronze and stainless steel components and can be protected with zinc or aluminum anodizes without worrying about overprotection. Overprotection is possible only if the weight of the anode is too large, causing the ship to sink! The voltage generated by the zinc or aluminum anode does not cause any damage, and the maximum voltage that can be generated is the voltage of the anode itself, no matter how much anode material is added, which is constant. Effective protection can be achieved by using magnesium anodes on fiberglass hulls in freshwater areas.

Be careful when using magnesium alloy anodes on aluminum or wooden boats, as overprotection may occur. Steel hulls need to be over-protected, and excessive protective voltages can strip paint off the hull.