Fishing chains have three specifications: short link chian, middle link chain and long link chain. Different types of fishing chains have different features.

Products

hot-sale products

-

Fishing Chains

Fishing Chains -

Studless Anchor Chain Fishing

Studless Anchor Chain FishingStudless Fishing Anchor Chain are 62.5% load verified at break, very durable and able to withstand extreme and harsh weather use, it is also corrosion-resistant, ideal for use in saltwater environments. There are Short Link, Mid Link and Long Link to choose from.

-

Stud Link Anchor Chain for Fish Chain

Stud Link Anchor Chain for Fish ChainStud link anchor chains are a type of heavy-duty chain commonly used for anchoring and mooring vessels. They have a central stud in each link that helps to prevent kinking, deformation, and fouling. These chains are known for their strength and are often preferred for large vessels and applications where significant loads are involved.

-

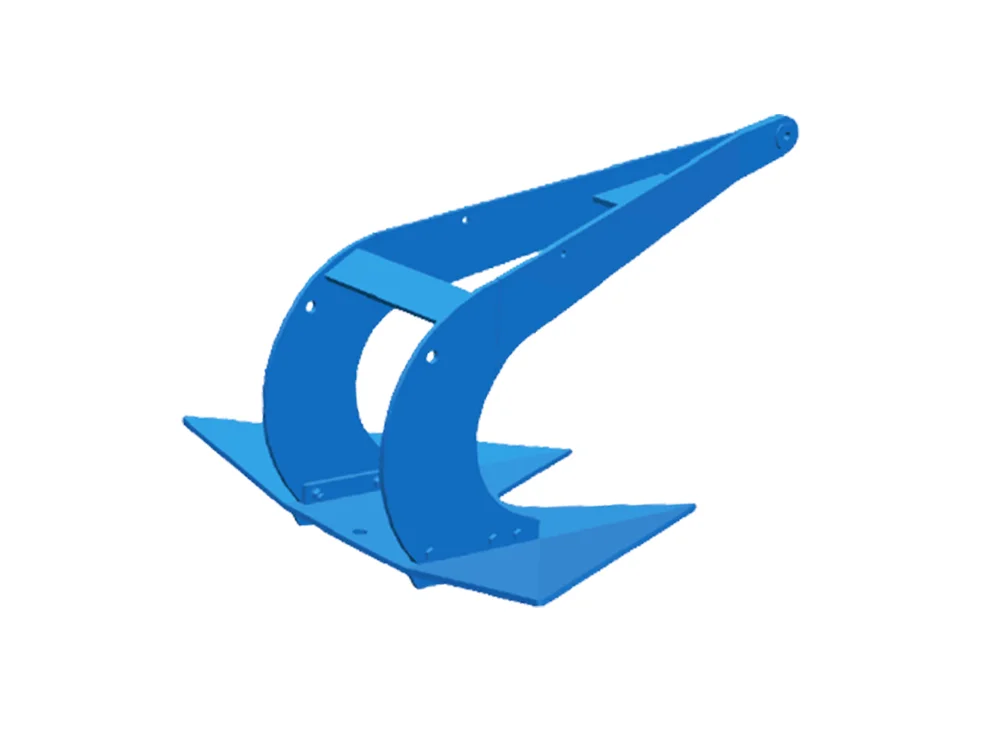

Dual Shank Anchor

Dual Shank AnchorThe dual shank anchor features two parallel shanks that work together to embed and hold in various seabed conditions. This design provides higher holding power than traditional anchors, especially in soft ground and mud, and is commonly used in aquaculture and swing moorings.

-

ADA Aqua Drag Anchor

ADA Aqua Drag AnchorADA aqua drag anchor is improved version base on generation of aqua-moor DSA anchor, yet provides better performance.

-

Sand Plough Anchor

Sand Plough AnchorA Sand Anchor has is a conventional anchor with solid construction to withstand high load.It has high holding power and weight ratio and very suitable for seabed of sand and mix Soil.

-

Aquaculture Mooring Plates

Aquaculture Mooring PlatesMooring connection plates are manufactured using alloy grade material and followed by full heat treatment process.The durability ensures that the plates can withstand exposure to saltwater, reducing maintenance needs and extending the lifespan of the aquaculture setup.

-

Aquaculture Mooring Shackle

Aquaculture Mooring ShackleMooring shackles are manufactured with alloy steel by following ISO9001 Quality Control System. With our years know-how on forging, heat treatment and hot dip galvanized, it is ensured the mooring shackle avoid any Hydrogen Embrittle-ment and offer a longer fatigue life of safe performance compared to EN13889 requirement and safety.

-

AM3 Stud Link Anchor Chain

AM3 Stud Link Anchor ChainAM3 is a designation for a grade of stud-link anchor chain, specifically referring to a high-strength steel chain used for ship anchoring and mooring. These chains are designed for durability and reliability in demanding marine applications, often used on large vessels or in harsh environmental conditions.

-

AM2 Stud Link Anchor Chain

AM2 Stud Link Anchor ChainStud link anchor chain AM2 is a specific type of anchor chain widely used in marine applications. It's characterized by having a stud (a crossbar or bar) within each link, adding strength and preventing kinking or twisting. AM2 is a designation within the marine industry for a specific grade of this chain, indicating its strength and material properties.

-

HDG Studless Anchor Chian

HDG Studless Anchor ChianAnchor Chain for marine farm mooring system, with diameter 16mm to 50mm, most used in European fish farming industry.

-

Type D End Anchor Shackle

Type D End Anchor ShackleAn Anchor Shackle Type D End Shackle is a specific type of shackle used in marine applications, particularly for connecting anchor chains. It's a D-shaped fitting with a removable pin, designed to safely connect the anchor's standard shackle to the chain or to a rope with a thimble.

ISO13755 Warping Roller Fairlead

| Attributes: | |

| Material: | Cast Steel |

| Surface: | Sandblasting then Painted Epoxy or According to the Customer's Request. |

| Size: | 160MM-500MM |

| SWL: | 265KN to 1942KN |

| Type: | Type A, Type B & Type C |

| Certification: | LR, ABS, DNV, BV, CCS, KR, RMRS, NK etc. |

ISO13755 Warping Roller Fairlead

The foundation of the warping roller shall be determined by the manufacturer in accordance with the standard of ISO13755. The roller fairlead is made from steel casting having a yield point of not less than 205N/mm2 or steel plates having a yield point of not less than 235 N/mm2 and the Axl is made from weldable steel casting having a yield point of not less than 350N/mm2 or equivalent. The warping roller has three types including type A which is made of steel casting without upper dust cover, type B which is made of steel casting with upper dust cover and type C which is made of steel plate with dust cover depending on the construction.

Features of ISO13755 Warping Roller Fairlead:

● Flexible bearing or axle;

● Smooth surface coated externally with an anti-corrosion protective finish;

● Anti-seawater material.

Drawings of ISO13755 Warping Roller Fairlead:

Specification of ISO13755 Warping Roller Fairlead:

| Nominal Size | Dimensions (mm) | SWL | 聽 | 聽 | 聽 | ||||||||

| (mm) | D1 | D2 | D3 | D4 | H | T | θ=90o | θ=0o | Weight for type A | Weight for type B | Weight for type C | ||

| (kN) | (t) | (kN) | (t) | (kg) | (kg) | (kg) | |||||||

| 150 | 150 | 230 | 216 | 90 | 137 | 22 | 265 | 27 | 186 | 19 | 23 | 24 | 21 |

| 200 | 200 | 300 | 280 | 115 | 157 | 26 | 441 | 45 | 314 | 32 | 42 | 43 | 37 |

| 250 | 250 | 370 | 340 | 135 | 177 | 30 | 579 | 59 | 412 | 42 | 77 | 80 | 56 |

| 300 | 300 | 430 | 400 | 150 | 197 | 32 | 726 | 74 | 510 | 52 | 109 | 112 | 86 |

| 350 | 350 | 490 | 460 | 167 | 217 | 34 | 1040 | 106 | 736 | 75 | 154 | 160 | 127 |

| 400 | 400 | 560 | 520 | 177 | 237 | 36 | 1246 | 127 | 883 | 90 | 207 | 215 | 174 |

| 450 | 450 | 620 | 590 | 190 | 257 | 38 | 1599 | 163 | 1128 | 115 | 275 | 286 | 215 |

| 500 | 500 | 680 | 660 | 205 | 277 | 40 | 1942 | 198 | 1373 | 140 | 360 | 374 | 253 |